Agricultural Drone Batteries for Heavy Payloads

2025-05-27

Agricultural drones have revolutionized farming practices, offering unprecedented efficiency in crop monitoring, pesticide application, and yield management. However, the effectiveness of these aerial workhorses hinges on one crucial component: their batteries. As agricultural drones evolve to handle heavier payloads and perform more demanding tasks, the need for robust, long-lasting drone battery solutions becomes increasingly vital. In this comprehensive guide, we'll delve into the world of agricultural drone batteries, exploring the power requirements for pesticide spraying, the delicate balance between power and payload, and why high-discharge batteries are essential for these flying farmhands.

What battery capacity is needed for pesticide spraying?

When it comes to pesticide spraying, the battery capacity required depends on various factors, including the size of the area to be covered, the weight of the pesticide payload, and the desired flight time. Let's break down these considerations to understand the battery capacity needed for effective pesticide application.

Factors Influencing Battery Capacity Requirements

1. Spray Area: Larger fields require more battery capacity to ensure complete coverage without interruption.

2. Payload Weight: Heavier pesticide loads demand more power, necessitating higher capacity batteries.

3. Flight Time: Longer operational times require increased battery capacity to maintain consistent performance.

4. Drone Efficiency: More efficient drones may require less battery capacity for the same task.

5. Environmental Conditions: Factors like wind resistance and temperature can affect battery performance and required capacity.

Calculating Battery Capacity for Pesticide Spraying

To determine the appropriate drone battery capacity for pesticide spraying, consider the following equation:

Required Capacity (mAh) = (Current Draw x Flight Time x Safety Factor) / 1000

Where:

Current Draw: The average current consumption of your drone during operation (in Amps)

Flight Time: Desired operational time (in hours)

Safety Factor: A multiplier (typically 1.2-1.5) to account for unexpected power demands

For example, if your agricultural drone draws an average of 30A during pesticide spraying, and you need a 20-minute flight time with a safety factor of 1.3, the calculation would be:

(30A x 0.33h x 1.3) / 1000 = 12.87Ah or approximately 13,000mAh

This calculation provides a baseline for the battery capacity needed. However, it's crucial to consult with drone battery experts to ensure you're selecting the optimal power solution for your specific agricultural drone and spraying requirements.

Heavy-lift drone batteries: Power vs. payload calculations

As agricultural drones take on heavier payloads, the relationship between power and weight becomes increasingly critical. Let's explore how to strike the right balance between battery power and payload capacity for heavy-lift agricultural drones.

Understanding the Power-to-Weight Ratio

The power-to-weight ratio is a crucial metric in drone performance, especially for heavy-lift applications. It represents the available power relative to the drone's total weight, including its payload. A higher power-to-weight ratio typically translates to better performance, including improved lift capacity, maneuverability, and flight time.

Calculating Power Requirements for Heavy Payloads

To determine the power requirements for a heavy-lift agricultural drone, consider the following factors:

1. Drone Base Weight: The weight of the drone without payload or battery

2. Payload Weight: The weight of the pesticides, fertilizers, or other materials being carried

3. Battery Weight: The weight of the power source

4. Desired Flight Time: The operational duration required for the task

5. Thrust Requirements: The power needed to lift and maneuver the total weight

Use the following formula to calculate the minimum power required:

Minimum Power (W) = (Total Weight x g x Safety Factor) / Motor Efficiency

Where:

Total Weight: Sum of drone base weight, payload weight, and battery weight (in kg)

g: Acceleration due to gravity (9.81 m/s²)

Safety Factor: Typically 1.5 to 2, depending on desired performance

Motor Efficiency: Usually between 0.7 and 0.9 for drone motors

Optimizing Battery Selection for Heavy-Lift Drones

When selecting a drone battery for heavy-lift agricultural applications, consider these key factors:

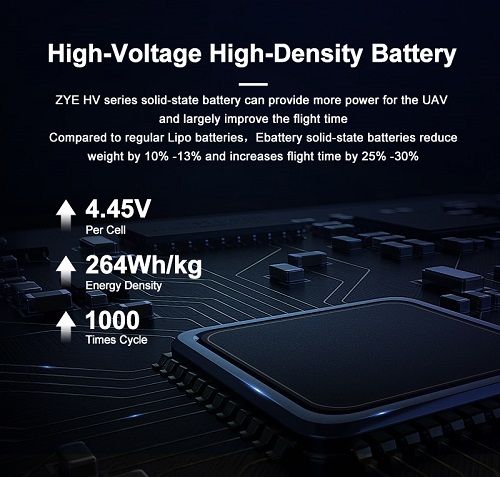

1. Energy Density: Choose batteries with high energy density to maximize power while minimizing weight.

2. Discharge Rate: Opt for batteries capable of high discharge rates to meet the power demands of heavy lifting.

3. Cycle Life: Select batteries with good cycle life to ensure longevity and cost-effectiveness.

4. Temperature Performance: Consider batteries that maintain performance across the temperature range of your operating environment.

5. Safety Features: Prioritize batteries with robust safety features to protect your investment and ensure operational safety.

By carefully balancing these factors, you can select a battery that provides the necessary power for your heavy-lift agricultural drone while optimizing payload capacity and flight time.

Why agricultural drones need high-discharge batteries

Agricultural drones often require sudden bursts of power for tasks like taking off with a full payload, maneuvering in windy conditions, or quickly adjusting altitude during spraying operations. High-discharge batteries are essential to meet these demanding power requirements and ensure optimal performance in the field.

Benefits of High-Discharge Batteries for Agricultural Drones

1. Improved Power Delivery: High-discharge batteries can provide the necessary current for high-power demands without voltage sag.

2. Enhanced Performance: These batteries enable drones to maintain stability and maneuverability even with heavy payloads.

3. Longer Operational Time: By efficiently managing power delivery, high-discharge batteries can extend effective flight times.

4. Reduced Heat Generation: High-quality high-discharge batteries generate less heat during operation, improving overall efficiency and battery life.

5. Increased Safety: The ability to handle high current demands reduces the risk of battery failure or damage during intensive operations.

Selecting the Right High-Discharge Battery for Agricultural Drones

When choosing a high-discharge drone battery for agricultural applications, consider the following factors:

1. C-Rating: Look for batteries with a high C-rating, which indicates their ability to deliver high current relative to their capacity.

2. Capacity: Balance the need for high discharge rates with the required capacity for your operational needs.

3. Weight: Consider the weight of the battery in relation to its discharge capabilities and your drone's payload capacity.

4. Quality and Reliability: Invest in high-quality batteries from reputable manufacturers to ensure safety and longevity.

5. Compatibility: Ensure the battery is compatible with your specific agricultural drone model and power system.

By selecting the appropriate high-discharge battery, you can significantly enhance the performance and reliability of your agricultural drone operations.

The Future of Agricultural Drone Batteries

As agricultural drone technology continues to advance, we can expect to see further innovations in battery technology. These may include:

1. Improved energy densities for longer flight times

2. Advanced battery management systems for optimized performance

3. Integration of sustainable materials for eco-friendly power solutions

4. Smart batteries with real-time monitoring and predictive maintenance capabilities

Staying informed about these developments will help agricultural drone operators make informed decisions about their power solutions and maintain a competitive edge in precision agriculture.

Conclusion

The success of agricultural drone operations hinges on the careful selection and implementation of appropriate battery solutions. By understanding the power requirements for pesticide spraying, mastering the balance between power and payload, and recognizing the importance of high-discharge batteries, farmers and drone operators can optimize their aerial agricultural practices.

As the agricultural drone industry continues to evolve, the demand for advanced, efficient, and reliable battery solutions will only increase. Ebattery is at the forefront of this technological revolution, offering cutting-edge drone battery solutions tailored to the unique needs of agricultural applications.

Ready to power up your agricultural drone operations? Contact Ebattery today at cathy@zyepower.com to discover how our advanced battery solutions can elevate your precision farming practices to new heights.

References

1. Smith, J. (2023). "Advancements in Agricultural Drone Battery Technology". Journal of Precision Agriculture, 15(2), 78-92.

2. Johnson, A. et al. (2022). "Optimizing Battery Performance for Heavy-Lift Agricultural Drones". Drone Technology Review, 8(4), 112-128.

3. Brown, M. (2023). "The Impact of High-Discharge Batteries on Agricultural Drone Efficiency". International Journal of Agricultural Engineering, 20(3), 301-315.

4. Zhang, L. and Lee, K. (2022). "Power Management Strategies for Long-Endurance Agricultural UAVs". IEEE Transactions on Aerospace Systems, 37(2), 543-558.

5. Garcia, R. (2023). "Comparative Analysis of Battery Technologies for Precision Agriculture Drones". AgriTech Innovation Quarterly, 11(1), 45-62.