What is the internal structure of a drone battery?

2025-09-29

Drone technology has revolutionized industries ranging from aerial photography to industrial applications. At the heart of these flying marvels lies a critical component: the drone lithium battery. The stable flight and operational capabilities of drones rely entirely on the precision engineering of these lithium batteries.

In this article, we will delve into the cells, chemistry, and structure of drone batteries, revealing the complexity that powers diverse unmanned aerial vehicles.

How many cells are in a standard drone battery?

The number of cells in a drone battery may vary based on the drone's size, power requirements, and intended use. However, most standard drone batteries typically contain multiple cells connected in series or parallel configurations.

Inside each cell, a positive electrode (such as ternary lithium material), negative electrode (graphite), electrolyte (ion conductor), and separator (preventing short circuits between electrodes) work together to achieve the core function of “storing energy during charging and delivering power during discharge.”

Most commercial and professional drones utilize multi-cell batteries to increase power and flight duration. The most common configurations include: 2S, 3S, 4S, and 6S.

LiPo (Lithium Polymer) batteries are the most prevalent type in drones, with each cell rated at 3.7V. Connecting cells in series increases the voltage, delivering greater power to the drone's motors and systems.

In a series configuration, cells are connected end-to-end, linking the positive terminal of one cell to the negative terminal of the next. This arrangement increases the overall voltage of the battery pack while maintaining the same capacity.

In a parallel configuration, batteries are connected with all positive terminals linked together and all negative terminals linked together. This arrangement increases the total capacity (mAh) of the battery pack while maintaining the same voltage.

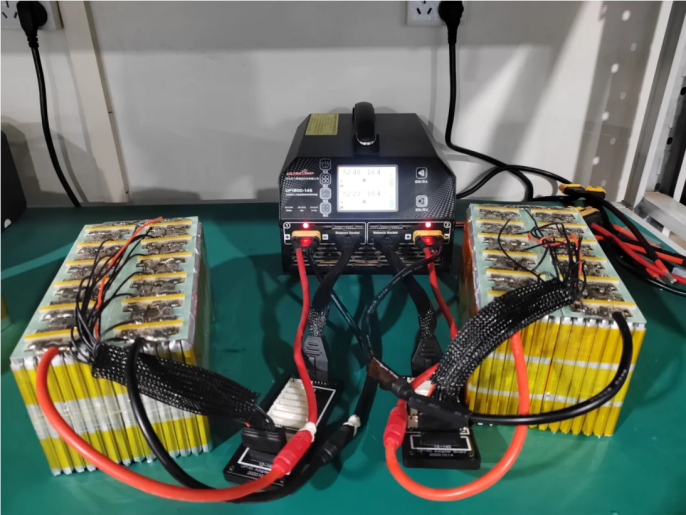

Regardless of configuration, modern drone batteries integrate sophisticated Battery Management Systems (BMS). These electronic circuits monitor and regulate individual cell voltages, ensuring balanced charging and discharging across all cells within the pack.

Internal Structure of Lithium Polymer Batteries: Anode, Cathode, and Electrolyte

To truly understand drone batteries, we must examine their internal components. Lithium polymer batteries, the power source behind most drones, consist of three primary elements: the anode, cathode, and electrolyte.

Anode: The Negative Electrode

The anode in a lithium polymer battery is typically made of graphite, a form of carbon. During discharge, lithium ions move from the anode to the cathode, releasing electrons that flow through the external circuit to power the drone.

Cathode: The Positive Electrode

The cathode is usually composed of a lithium metal oxide, such as lithium cobalt oxide (LiCoO₂) or lithium iron phosphate (LiFePO₄). The choice of cathode material influences the battery's performance characteristics, including energy density and safety.

Electrolyte: The Ion Highway

The electrolyte in a lithium polymer battery is a lithium salt dissolved in an organic solvent. This component enables lithium ions to migrate between the anode and cathode during charge and discharge cycles. A unique feature of lithium polymer batteries is that this electrolyte is immobilized within a polymer composite, making the battery more flexible and less prone to damage.

Protective Support: Housing and Connectors

Beyond the core module, the drone battery's housing and connectors—though not directly involved in power delivery—serve as the “skeleton” ensuring structural integrity:

Housing: Typically constructed from flame-retardant ABS plastic or aluminum alloy, offering impact resistance, flame retardancy, and thermal insulation. It incorporates ventilation holes to prevent overheating during cell operation.

Connectors and Interfaces: Internal multi-strand copper wires (highly conductive and bend-resistant) connect the cells to the BMS. External interfaces commonly use XT60 or XT90 connectors with reverse-plug protection to prevent accidental damage from incorrect connections.

Basic Maintenance: Protect internal components to extend battery lifespan

Avoid overcharging or over-discharging (store between 20%-80% capacity) to prevent BMS overload and cell degradation;

Avoid water ingress when cleaning connectors to prevent short circuits in wiring;

Replace damaged casings promptly to shield internal cells and BMS from physical impact.

The internal architecture of drone batteries represents a precise synergy of “energy, control, and protection.” With advancements in solid-state batteries and intelligent BMS technology, future battery designs will become more compact and efficient, providing core support for drone performance upgrades.