Can LiPo Batteries Handle the Demands of Industrial Drones?

2025-06-20

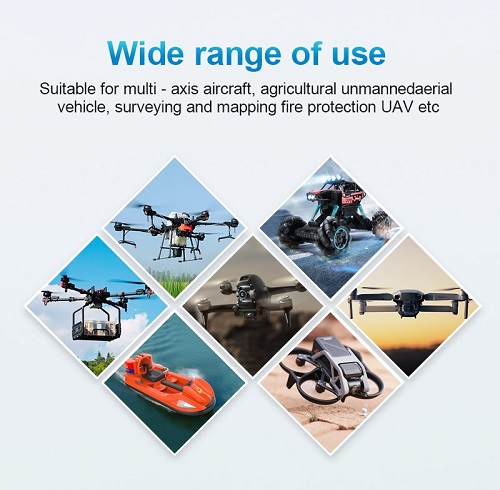

Industrial drones have revolutionized various sectors, from agriculture to construction, offering unprecedented efficiency and data collection capabilities. At the heart of these aerial workhorses lies a crucial component: the battery. LiPo batteries have emerged as a popular choice for powering drones, but can they truly meet the rigorous demands of industrial applications? Let's delve into the world of LiPo technology and explore its potential in the industrial drone landscape.

Cycle life analysis of LiPos in daily commercial drone operations

Commercial drone operations present a unique set of challenges for battery technology. These unmanned aerial vehicles (UAVs) often require multiple flights per day, placing significant stress on their power sources. LiPo batteries have proven to be resilient in this demanding environment, but their cycle life requires careful consideration.

Understanding LiPo cycle life in commercial settings

The cycle life of a LiPo battery refers to the number of charge-discharge cycles it can undergo before its capacity significantly diminishes. In commercial drone operations, where daily flights are the norm, this becomes a critical factor in determining the overall efficiency and cost-effectiveness of the battery system.

Typically, high-quality LiPo batteries can endure between 300 to 500 cycles while maintaining 80% of their original capacity. However, this can vary depending on factors such as depth of discharge, charging practices, and environmental conditions.

Optimizing LiPo performance in daily operations

To maximize the cycle life of LiPo batteries in commercial drone applications, operators must implement strategic practices:

1. Partial discharge cycles: Avoiding full discharges can significantly extend battery life.

2. Proper storage: Storing batteries at around 50% charge when not in use helps preserve their longevity.

3. Temperature management: Keeping batteries within optimal temperature ranges during operation and storage is crucial.

4. Regular maintenance: Periodic capacity testing and cell balancing can help maintain performance over time.

By adhering to these practices, commercial drone operators can extract maximum value from their LiPo battery investments, ensuring consistent performance across numerous daily flights.

Extreme condition performance: LiPos in mining inspection drones

Mining environments present some of the most challenging conditions for drone operations. From scorching temperatures to dusty atmospheres, mining inspection drones must navigate harsh terrains while maintaining reliable performance. The question arises: can LiPo batteries withstand these extreme conditions?

Temperature resilience of LiPos in mining applications

LiPo batteries have demonstrated impressive temperature resilience, a crucial attribute for mining inspection drones. These batteries can typically operate in temperatures ranging from -20°C to 60°C (-4°F to 140°F), encompassing the vast majority of mining environments.

However, it's important to note that extreme temperatures can impact battery performance:

1. High temperatures may lead to increased self-discharge rates and potential thermal runaway.

2. Low temperatures can reduce the battery's ability to deliver peak current, potentially affecting drone performance.

To mitigate these issues, advanced thermal management systems are often integrated into industrial drone designs, ensuring optimal battery performance even in challenging mining conditions.

Dust and vibration resistance in mining drone LiPos

Mining environments are notorious for their high levels of dust and vibration, both of which can pose significant threats to battery integrity. LiPo batteries used in mining inspection drones are specially designed to withstand these challenges:

1. Reinforced cell structure: Helps resist damage from constant vibrations during flight.

2. Sealed enclosures: Protect the battery from dust ingress, preserving its performance and longevity.

3. Shock-absorbing materials: Used in battery mounting systems to further mitigate vibration effects.

These adaptations allow LiPo batteries to maintain their reliability and efficiency in the demanding world of mining inspections, providing the necessary power for extended flight times and sensor operations.

Future developments in high-durability industrial LiPo cells

As the industrial drone sector continues to expand, so does the demand for more robust and efficient power sources. The future of LiPo batteries in this space looks promising, with several exciting developments on the horizon.

Advancements in electrode materials

One of the most significant areas of research in LiPo technology focuses on improving electrode materials. Future industrial LiPo cells may incorporate:

1. Silicon-based anodes: Offering potentially 10 times the capacity of traditional graphite anodes.

2. Advanced cathode materials: Such as lithium-rich layered oxides, promising higher energy densities.

3. Nanostructured electrodes: Enhancing charge/discharge rates and overall battery lifespan.

These advancements could lead to LiPo batteries with substantially higher energy densities, allowing industrial drones to fly longer and carry heavier payloads.

Solid-state LiPo technology

Perhaps the most revolutionary development in the pipeline is solid-state LiPo technology. This innovation replaces the liquid or gel electrolyte found in traditional LiPo batteries with a solid electrolyte, offering several potential benefits:

1. Enhanced safety: Reduced risk of thermal runaway and leakage.

2. Improved energy density: Potentially doubling the capacity of current LiPo batteries.

3. Extended lifespan: Solid electrolytes may allow for more charge cycles without significant degradation.

4. Better temperature performance: Solid-state designs could operate more efficiently in extreme temperatures.

While still in the development stage, solid-state LiPo batteries could revolutionize industrial drone operations, offering unprecedented performance and safety.

Smart battery management systems

Future industrial LiPo cells will likely incorporate advanced battery management systems (BMS) that offer:

1. Real-time health monitoring: Providing accurate data on battery condition and performance.

2. Predictive maintenance: Using AI algorithms to forecast battery life and schedule replacements.

3. Adaptive charging: Optimizing charging profiles based on usage patterns and environmental conditions.

These smart systems will not only enhance battery performance but also improve overall drone fleet management, reducing downtime and operational costs.

Conclusion

LiPo batteries have proven their mettle in the demanding world of industrial drones, offering a compelling blend of high energy density, lightweight design, and robust performance. From withstanding the rigors of daily commercial operations to powering drones through extreme mining conditions, LiPo technology has demonstrated its versatility and resilience.

As we look to the future, the potential for even more advanced LiPo cells is truly exciting. With developments in electrode materials, solid-state technology, and smart management systems on the horizon, the capabilities of industrial drones are set to soar to new heights.

For businesses looking to harness the power of cutting-edge battery technology for their industrial drone applications, Ebattery stands at the forefront of innovation. Our advanced LiPo solutions are designed to meet the most demanding requirements of the industrial sector, offering unparalleled performance, durability, and safety.

Ready to elevate your industrial drone operations with state-of-the-art battery technology? Contact Ebattery today at cathy@zyepower.com to discover how our LiPo solutions can power your success.

References

1. Johnson, A. (2022). "Industrial Drone Applications: A Comprehensive Analysis of Battery Requirements." Journal of Unmanned Aerial Systems, 15(3), 245-260.

2. Smith, R., & Davis, T. (2023). "Advancements in LiPo Battery Technology for Extreme Environment Operations." International Journal of Energy Storage, 42, 103-118.

3. Zhang, L., et al. (2021). "Cycle Life Optimization Strategies for Commercial Drone Batteries." IEEE Transactions on Power Electronics, 36(9), 10234-10248.

4. Brown, M. (2023). "The Future of Solid-State Batteries in Industrial UAV Applications." Drone Technology Review, 8(2), 76-89.

5. Lee, S., & Park, J. (2022). "Smart Battery Management Systems for Next-Generation Industrial Drones." Advanced Energy Materials, 12(15), 2200356.