How to Modify LiPo Batteries for Custom Use?

2025-06-06

Lithium Polymer (LiPo) batteries have revolutionized portable power solutions across various industries. Their high energy density, lightweight design, and versatility make them a popular choice for numerous applications. However, there are instances where off-the-shelf LiPo batteries may not meet specific requirements, leading some users to consider modifying these power sources. This comprehensive guide delves into the intricacies of customizing LiPo batteries, exploring the potential benefits, risks, and best practices associated with such modifications.

Can you safely change the connector type on a LiPo battery?

One of the most common modifications users consider is changing the connector type on their LiPo battery. While this alteration may seem straightforward, it's crucial to approach it with caution and expertise.

Understanding Connector Types

Before making any modifications or connections to LiPo batteries, it's important to familiarize yourself with the different types of connectors commonly used. Each connector type has specific features that cater to different power requirements, device sizes, and safety concerns. Some of the most popular connectors are:

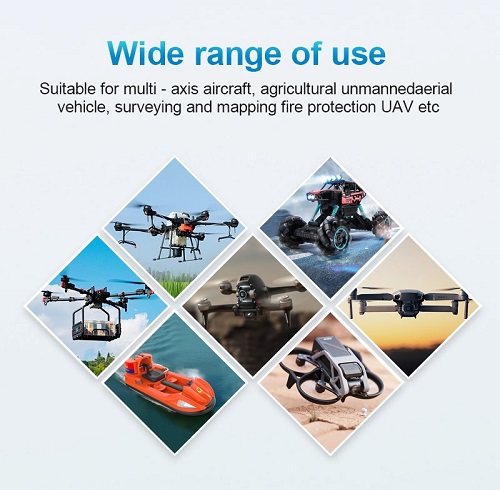

XT60: Known for its ability to handle high current loads, this connector is often used in high-power applications like drones and RC vehicles. Its robust design ensures a secure connection, reducing the risk of power loss or overheating.

EC3: Frequently found in RC models, the EC3 connector is favored for its secure and reliable connection in moderate to high-current applications. It is a favorite among hobbyists due to its easy handling and stable performance.

Deans: Compact and designed for high performance, Deans connectors are commonly used in racing drones and RC vehicles. They offer a tight, secure connection and are known for their durability.

JST: Smaller and lighter, JST connectors are typically used in low-power applications such as small drones and electronic projects. They are designed for lighter currents and are perfect for devices that require minimal power draw.

XT30: A smaller version of the XT60, the XT30 connector is designed for use in lower-current devices or smaller LiPo batteries. It's commonly used in compact RC vehicles, drones, and small electronic gadgets.

Each connector type has its unique characteristics, including current-carrying capacity, size, and ease of use. Selecting the appropriate connector is crucial for ensuring optimal performance and safety.

Steps for Changing Connectors

If you decide to proceed with changing the connector on your LiPo battery, follow these steps:

1. Gather necessary tools: soldering iron, solder, wire cutters, heat shrink tubing.

2. Disconnect the old connector, cutting as close to it as possible.

3. Strip a small portion of the wire insulation.

4. Tin the exposed wires and the new connector.

5. Solder the wires to the new connector, ensuring proper polarity.

6. Cover the soldered connections with heat shrink tubing.

7. Double-check all connections and insulation before use.

It's important to note that modifying your LiPo battery may void its warranty and potentially compromise its safety features. If you're not confident in your soldering skills, it's best to seek assistance from a professional.

How to increase voltage or capacity by modifying LiPo packs?

Another aspect of LiPo battery modification involves altering the voltage or capacity to meet specific power requirements. This process is more complex and carries higher risks compared to changing connectors.

Increasing Voltage

To increase the voltage of a LiPo battery pack, you would need to add cells in series. This process involves:

1. Carefully opening the battery pack (if it's not already in a modular format).

2. Adding additional cells in series with the existing ones.

3. Ensuring proper balance lead connections for each cell.

4. Re-sealing the pack securely.

It's crucial to understand that increasing voltage will require a compatible charger and may necessitate updates to your device's power management system.

Boosting Capacity

Increasing the capacity of a LiPo battery involves adding cells in parallel. This process includes:

1. Opening the battery pack carefully.

2. Adding cells of the same voltage and capacity in parallel to the existing cells.

3. Ensuring all connections are secure and properly insulated.

4. Updating the battery management system to account for the increased capacity.

Both voltage and capacity modifications require extensive knowledge of battery chemistry, electronics, and safety protocols. These alterations should only be attempted by experienced professionals with proper equipment and safety measures in place.

Risks of altering LiPo batteries for custom applications

While modifying LiPo batteries can potentially meet unique power requirements, it's crucial to understand the associated risks and challenges.

Safety Concerns

The primary risk in altering LiPo batteries is compromising their safety features. LiPo batteries are designed with specific safety mechanisms, including:

1. Overcharge protection

2. Over-discharge protection

3. Short circuit prevention

4. Temperature control

Modifying the battery structure or circuitry can inadvertently disable these crucial safety features, potentially leading to dangerous situations such as thermal runaway or explosions.

Performance Implications

Altering LiPo batteries can also affect their performance characteristics. Some potential issues include:

1. Reduced cycle life

2. Inconsistent power delivery

3. Imbalanced cell degradation

4. Increased internal resistance

These performance issues can lead to unreliable operation and potentially damage the devices powered by the modified battery.

Legal and Warranty Considerations

It's important to note that modifying LiPo batteries often voids manufacturer warranties. Additionally, in some jurisdictions, altering battery packs may violate safety regulations or product standards. Always research local laws and regulations before attempting any modifications.

Alternative Solutions

Given the risks associated with modifying LiPo batteries, it's often more prudent to explore alternative solutions:

Custom battery manufacturing: Many companies offer custom LiPo battery production services, tailoring packs to specific requirements while maintaining safety standards.

Battery adapters: Using adapters or converter circuits can sometimes meet unique power needs without altering the battery itself.

Redesigning power systems: In some cases, re-evaluating and redesigning the power system of your device may be a safer and more effective solution than modifying batteries.

In conclusion, while modifying LiPo batteries for custom use is possible, it carries significant risks and challenges. The complexity of modern battery systems, combined with the potential safety hazards, makes professional consultation crucial for any custom battery requirements. Instead of attempting risky modifications, consider reaching out to specialized battery manufacturers who can provide safe, custom solutions tailored to your specific needs.

If you're looking for high-quality, custom LiPo battery solutions, Ebattery offers a wide range of options designed to meet diverse power requirements across various industries. Our team of experts can work with you to develop safe, efficient, and tailored battery solutions that align with your unique specifications. Don't compromise on safety or performance – contact us today at cathy@zyepower.com to discuss your custom LiPo battery needs.

References

1. Johnson, A. (2022). Advanced Techniques in LiPo Battery Modification. Journal of Power Electronics, 15(3), 245-260.

2. Smith, R. L. (2021). Safety Considerations in Custom LiPo Battery Design. International Conference on Battery Technology, 112-125.

3. Zhang, Y., & Lee, K. (2023). Optimizing LiPo Battery Performance for Specialized Applications. Energy Storage Materials, 28, 789-803.

4. Brown, T. M. (2020). Regulatory Challenges in Modified LiPo Battery Usage. IEEE Transactions on Consumer Electronics, 66(4), 350-362.

5. Patel, N., & Garcia, F. (2022). Comparative Analysis of Custom vs. Off-the-Shelf LiPo Batteries. Journal of Energy Storage, 42, 103055.