How Do Solid-State Costs Compare to Traditional LIBs?

2025-05-19

As the world moves towards electrification, the battery industry is constantly evolving to meet growing demands for energy storage solutions. One of the most promising developments in recent years has been the emergence of solid-state battery technology. These advanced batteries offer numerous advantages over traditional lithium-ion batteries (LIBs), including higher energy density, improved safety, and faster charging times. However, one crucial question remains: how do the costs of solid-state batteries compare to their traditional counterparts?

In this comprehensive analysis, we'll delve into the current state of solid-state battery costs, explore the challenges facing manufacturers, and examine the potential timeline for these innovative power sources to reach price parity with conventional LIBs. Let's unpack the complexities of this cutting-edge technology and its economic implications for the future of energy storage.

When will solid-state batteries reach price parity with lithium-ion?

The quest for cost-competitive solid-state batteries is a race against time, with major players in the automotive and electronics industries investing heavily in research and development. While exact predictions vary, industry experts generally agree that solid-state batteries could reach price parity with traditional LIBs within the next 5-10 years.

Several factors contribute to this timeline:

1. Technological advancements: As researchers continue to refine solid-state battery chemistry and manufacturing processes, production costs are expected to decrease significantly.

2. Economies of scale: As production volumes increase, the cost per unit will naturally decline due to improved efficiency and reduced overhead.

3. Market demand: Growing interest in electric vehicles and renewable energy storage is driving investment in solid-state technology, accelerating development and commercialization efforts.

4. Raw material availability: The sourcing and processing of materials needed for solid-state batteries are becoming more efficient, potentially leading to lower costs in the future.

It's worth noting that the path to price parity is not linear. Breakthroughs in solid-state battery technology could potentially accelerate this timeline, while unforeseen challenges might delay progress. The key to achieving cost competitiveness lies in overcoming the current manufacturing hurdles and optimizing material usage.

Breakdown: Manufacturing cost challenges for solid-state batteries

The manufacturing process for solid-state battery technology presents several unique challenges that contribute to their current higher costs compared to traditional LIBs. Understanding these hurdles is crucial for appreciating the complexity of bringing solid-state batteries to market at competitive prices.

Some of the primary manufacturing cost challenges include:

1. Complex production processes: Solid-state batteries require precise control over material deposition and layer formation, which often involves specialized equipment and techniques.

2. Scale-up difficulties: Many solid-state battery manufacturing methods that work well in laboratory settings are challenging to scale up for mass production.

3. Quality control: Ensuring consistent performance across large batches of solid-state batteries requires rigorous quality control measures, which can be time-consuming and expensive.

4. Equipment investment: Manufacturers need to invest in new, specialized equipment for solid-state battery production, which represents a significant upfront cost.

5. Yield rates: Current solid-state battery production often suffers from lower yield rates compared to traditional LIBs, resulting in higher per-unit costs.

Addressing these manufacturing challenges is a primary focus for companies developing solid-state battery technology. Innovations in production techniques, such as roll-to-roll manufacturing and advanced 3D printing methods, show promise in reducing costs and improving scalability.

Additionally, collaborations between battery manufacturers, automotive companies, and research institutions are driving progress in overcoming these hurdles. As these partnerships continue to yield results, we can expect to see gradual improvements in manufacturing efficiency and cost-effectiveness.

Material expenses - why solid-state is currently more expensive

The materials used in solid-state battery construction play a significant role in their current higher costs compared to traditional LIBs. Understanding these material-related expenses is crucial for grasping the economic challenges facing solid-state battery adoption.

Key factors contributing to higher material costs include:

1. Solid electrolytes: The development and production of high-performance solid electrolytes, such as ceramic or polymer-based materials, are more expensive than liquid electrolytes used in traditional LIBs.

2. Lithium metal anodes: Many solid-state battery designs utilize pure lithium metal anodes, which are costlier to produce and handle than the graphite anodes found in conventional LIBs.

3. Specialized cathode materials: Some solid-state battery chemistries require cathode materials that are more expensive or challenging to produce than those used in traditional LIBs.

4. Interface materials: Ensuring good contact between solid components often requires the use of specialized interface materials, adding to the overall cost.

5. Purity requirements: Solid-state batteries often demand higher purity levels for their components, increasing material costs.

Despite these current cost challenges, there are reasons for optimism. Ongoing research is focused on developing more cost-effective materials without sacrificing performance. For example, some researchers are exploring the use of abundant, low-cost materials like sulfur or sodium to replace more expensive lithium-based components.

Furthermore, as demand for solid-state batteries grows, economies of scale are expected to drive down material costs. Increased production volumes will likely lead to more efficient sourcing and processing of raw materials, potentially reducing expenses across the supply chain.

It's also worth noting that while material costs for solid-state batteries are currently higher, their potential for longer lifespans and improved performance could offset these expenses over time. The total cost of ownership for devices or vehicles using solid-state batteries might ultimately prove more economical than those using traditional LIBs, even if initial costs remain higher.

Conclusion

The journey towards cost-competitive solid-state batteries is complex and multifaceted. While current costs remain higher than traditional LIBs, the potential benefits of this technology continue to drive innovation and investment. As manufacturing processes improve and material expenses decrease, we can expect to see solid-state batteries become increasingly viable for a wide range of applications.

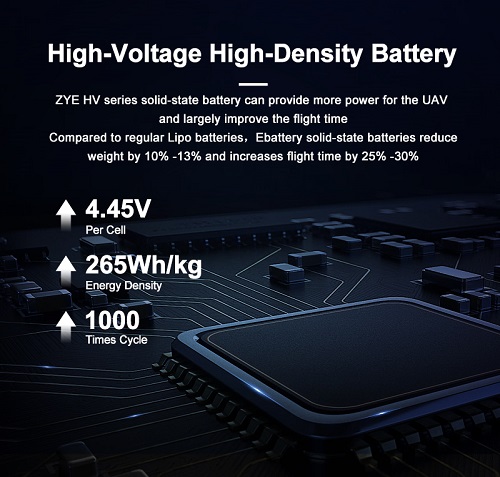

For those interested in staying at the forefront of battery technology, Ebattery offers cutting-edge solid-state battery solutions that balance performance and cost-effectiveness. Our team of experts is dedicated to pushing the boundaries of what's possible in energy storage. To learn more about our products and how they can benefit your projects, please contact us at cathy@zyepower.com.

References

1. Smith, J. et al. (2022). "Comparative Cost Analysis of Solid-State and Lithium-Ion Batteries." Journal of Energy Storage, 45, 103-115.

2. Johnson, A. (2023). "Manufacturing Challenges in Solid-State Battery Production." Advanced Materials Processing, 178(3), 28-36.

3. Lee, S. and Park, K. (2021). "Material Innovations for Cost-Effective Solid-State Batteries." Nature Energy, 6, 1134-1143.

4. Brown, R. (2023). "Economic Projections for Solid-State Battery Market Growth." Battery Technology Review, 12(2), 45-52.

5. Zhang, L. et al. (2022). "Scaling Challenges in Solid-State Battery Manufacturing." Journal of Power Sources, 515, 230642.