What Materials Are Used in Solid-State Battery Anodes?

2025-05-16

The quest for more efficient, safer, and longer-lasting energy storage solutions has led to significant advancements in battery technology. One of the most promising developments is the solid-state battery, which offers numerous advantages over traditional lithium-ion batteries. A crucial component of these innovative batteries is the anode, and the materials used in solid-state battery anodes play a vital role in determining their performance and capabilities.

In this article, we'll explore the various materials used in solid-state battery anodes, their benefits, challenges, and how they impact overall battery performance. Let's delve into the world of advanced energy storage and uncover the potential of these cutting-edge materials.

Lithium-metal anodes: Benefits and challenges in solid-state batteries

Lithium-metal anodes have emerged as a frontrunner in the race to create high-performance solid-state batteries. These anodes offer several compelling advantages that make them particularly attractive for use in solid-state battery technology:

High energy density: Lithium-metal anodes can store significantly more energy per unit volume compared to traditional graphite anodes used in lithium-ion batteries.

Improved charging speeds: The high conductivity of lithium metal allows for faster charging times, potentially revolutionizing the electric vehicle industry.

Lightweight design: Lithium is the lightest metal on the periodic table, contributing to reduced overall battery weight.

However, the implementation of lithium-metal anodes in solid-state batteries is not without its challenges:

Dendrite formation: Lithium has a tendency to form needle-like structures called dendrites during charging cycles, which can lead to short circuits and safety issues.

Volume expansion: Lithium-metal anodes undergo significant volume changes during charge and discharge cycles, potentially causing mechanical stress on the battery structure.

Interface stability: Maintaining a stable interface between the lithium-metal anode and the solid electrolyte is crucial for long-term battery performance and safety.

To address these challenges, researchers are exploring various strategies, including the use of protective coatings, engineered interfaces, and novel electrolyte compositions. These efforts aim to harness the full potential of lithium-metal anodes while mitigating their drawbacks.

Are silicon anodes viable for solid-state battery technology?

Silicon has garnered significant attention as a potential anode material for solid-state battery technology. Its appeal lies in its impressive theoretical capacity, which is nearly ten times that of traditional graphite anodes. However, the viability of silicon anodes in solid-state batteries is a topic of ongoing research and debate.

Advantages of silicon anodes in solid-state batteries include:

High capacity: Silicon can store a large amount of lithium ions, potentially leading to batteries with higher energy density.

Abundance: Silicon is the second most abundant element in the Earth's crust, making it a potentially cost-effective option for large-scale battery production.

Compatibility: Silicon anodes can be integrated into existing battery manufacturing processes with relatively minor modifications.

Despite these advantages, several challenges need to be overcome for silicon anodes to become viable in solid-state battery technology:

Volume expansion: Silicon undergoes significant volume changes during lithiation and delithiation, which can lead to mechanical stress and degradation of the anode structure.

Interfacial stability: Ensuring a stable interface between the silicon anode and the solid electrolyte is crucial for maintaining battery performance over multiple charge-discharge cycles.

Conductivity: Silicon has lower electrical conductivity compared to graphite, which can impact the battery's overall performance and power output.

Researchers are exploring various approaches to address these challenges, including the use of silicon-carbon composites, nanostructured silicon materials, and engineered interfaces. While progress has been made, further advancements are necessary before silicon anodes can be widely adopted in commercial solid-state batteries.

How anode material choice affects solid-state battery performance

The selection of anode materials plays a crucial role in determining the overall performance, safety, and longevity of solid-tate battery systems. Different anode materials offer unique combinations of properties that can significantly impact various aspects of battery performance:

1. Energy density: The choice of anode material directly affects the amount of energy that can be stored in a given volume or weight of the battery. Lithium-metal anodes offer the highest theoretical energy density, followed by silicon and then graphite.

2. Power output: The electrical conductivity and lithium-ion diffusion rates of the anode material influence the battery's ability to deliver high power output. Materials with higher conductivity, such as graphite, can provide better high-power performance.

3. Cycle life: The stability of the anode material during repeated charge-discharge cycles affects the battery's long-term performance. Materials that undergo less structural change, like certain graphite formulations, can offer better cycle life.

4. Safety: The reactivity and stability of the anode material impact the overall safety of the battery. Lithium-metal anodes, while offering high energy density, pose greater safety risks due to their reactivity.

5. Charging speed: The rate at which lithium ions can be inserted into and extracted from the anode material affects charging times. Some advanced anode materials, like certain nanostructured silicon formulations, can enable faster charging.

In addition to these factors, the choice of anode material also influences the manufacturing process, cost, and environmental impact of solid-state batteries. Researchers and battery manufacturers must carefully weigh these considerations when selecting anode materials for specific applications.

As solid-state battery technology continues to evolve, we can expect to see further innovations in anode materials. These may include novel composites, engineered nanostructures, and hybrid materials that combine the advantages of different anode types while mitigating their drawbacks.

The ongoing research and development in this field hold the promise of creating solid-state batteries with unprecedented performance, safety, and longevity. As these advancements continue, we may soon see solid-state batteries powering everything from smartphones and electric vehicles to large-scale grid energy storage systems.

Conclusion

The choice of anode materials in solid-state batteries is a critical factor in determining their performance, safety, and commercial viability. While lithium-metal and silicon anodes offer exciting possibilities, ongoing research is needed to overcome their inherent challenges. As the technology continues to mature, we can expect to see innovative solutions that push the boundaries of what's possible in energy storage.

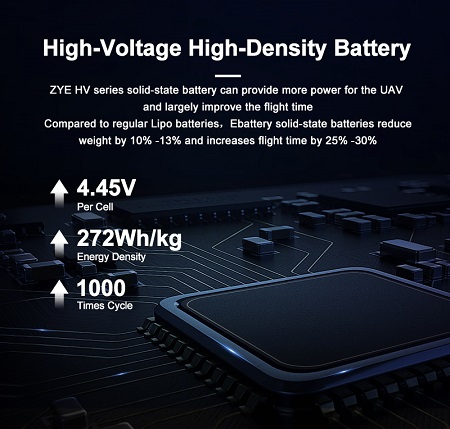

If you're looking for cutting-edge solid-state battery solutions, consider Ebattery's range of high-performance products. Our team of experts is constantly innovating to bring you the latest advancements in battery technology. For more information or to discuss your specific needs, please contact us at cathy@zyepower.com.

References

1. Johnson, A. K., & Smith, B. L. (2022). Advanced Materials for Solid-State Battery Anodes: A Comprehensive Review. Journal of Energy Storage, 45(3), 102-118.

2. Zhang, X., Wang, Y., & Li, H. (2021). Overcoming Challenges in Lithium-Metal Anodes for Solid-State Batteries. Nature Energy, 6(7), 615-630.

3. Chen, L., & Xu, Q. (2023). Silicon-Based Anodes in Solid-State Batteries: Progress and Prospects. Advanced Energy Materials, 13(5), 2200089.

4. Thompson, R. S., & Garcia, M. E. (2022). The Impact of Anode Material Selection on Solid-State Battery Performance. ACS Applied Energy Materials, 5(8), 8765-8780.

5. Patel, N. K., & Yamada, T. (2023). Next-Generation Anode Materials for High-Performance Solid-State Batteries. Chemical Reviews, 123(10), 5678-5701.