What is the problem with solid-state batteries?

2025-03-24

Solid-state batteries have been hailed as the next big breakthrough in energy storage technology, promising higher energy density, faster charging times, and improved safety compared to traditional lithium-ion batteries. However, despite their potential, these advanced power sources have yet to make a significant impact on the market. In this article, we'll explore the key challenges facing solid state batteries and why they haven't become commonplace in our devices and electric vehicles.

Why are solid-state batteries not yet widely adopted?

The slow adoption of solid-state batteries can be attributed to a variety of factors, with technical challenges being among the most prominent. While solid state batteries have shown promising results in laboratory settings, translating these achievements into practical, real-world applications has proven to be a significant hurdle.

One of the primary issues lies in the interface between the solid electrolyte and the electrodes. In traditional lithium-ion batteries, the liquid electrolyte can easily flow and adapt to the surface of the electrodes, ensuring consistent contact. However, in solid-state batteries, maintaining reliable contact between the solid electrolyte and the electrodes is much more difficult. This lack of a seamless connection can lead to diminished performance and the potential for degradation over time, making it challenging to achieve the desired efficiency and longevity in these batteries.

Another major challenge is the formation of dendrites—small, needle-like structures that can develop from the anode and penetrate the electrolyte. In solid-state batteries, dendrites can cause internal short circuits, which might lead to battery failure or even safety risks. While researchers are actively developing new materials and manufacturing techniques to address this issue, dendrite formation remains one of the key obstacles to the widespread use of solid-state batteries.

Additionally, temperature sensitivity poses another limitation. Many solid electrolytes tend to perform optimally only at higher temperatures, which restricts their practical use in a variety of applications, particularly in consumer electronics and electric vehicles. These devices require batteries that can function efficiently across a broad spectrum of environmental conditions, making temperature sensitivity a critical challenge to overcome.

What are the manufacturing challenges associated with solid-state batteries?

The production of solid-state batteries presents unique manufacturing challenges that have hindered their commercialization. One of the primary difficulties lies in scaling up production from small, laboratory-scale prototypes to large-scale manufacturing processes suitable for mass production.

The fabrication of solid electrolytes requires precise control over material composition and processing conditions. Many solid electrolytes are highly sensitive to moisture and air, necessitating specialized manufacturing environments with strict humidity and atmospheric controls. This adds complexity and cost to the production process.

Another manufacturing challenge is achieving uniform and defect-free interfaces between the solid electrolyte and electrodes. Any imperfections or gaps in these interfaces can significantly impact battery performance and longevity. Developing reliable and cost-effective techniques to create these interfaces at scale is an ongoing area of research and development.

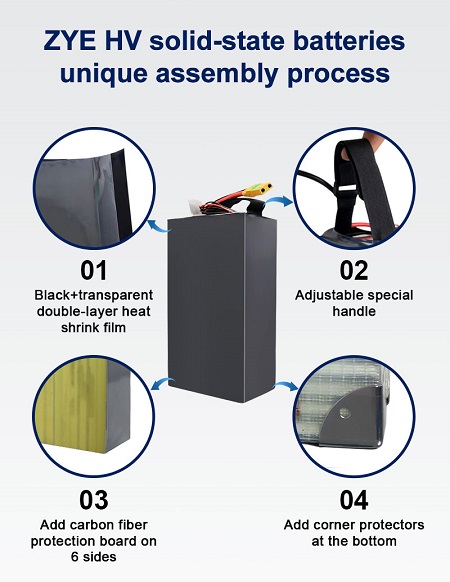

The assembly of solid-state batteries also requires new manufacturing techniques and equipment. Traditional battery production lines are designed for liquid electrolyte systems and are not directly applicable to solid-state battery manufacturing. This means that significant investments in new production facilities and equipment are necessary to bring solid-state batteries to market.

Furthermore, the materials used in solid state batteries often require high-temperature processing, which can be energy-intensive and expensive. Developing more efficient and cost-effective manufacturing methods is crucial for making solid-state batteries commercially viable.

What are the current cost barriers for solid-state battery technology?

The high cost of solid-state batteries is currently one of the most significant barriers to their widespread adoption. Several factors contribute to their elevated price point compared to traditional lithium-ion batteries.

Firstly, the materials used in solid-state batteries are often more expensive than those in conventional batteries. High-performance solid electrolytes, such as ceramic or glass-based materials, can be costly to produce and process. Additionally, some solid-state battery designs require specialized electrode materials, further increasing the overall material costs.

The complex manufacturing processes required for solid state batteries also contribute to their high cost. As mentioned earlier, specialized production environments and new manufacturing equipment are necessary, which requires significant capital investment. Until production can be scaled up and optimized, these costs will continue to be reflected in the final product price.

Research and development costs are another factor driving up the price of solid-state batteries. Considerable resources are being invested in overcoming technical challenges and improving battery performance. These R&D expenses are often factored into the cost of early commercial products.

Moreover, the current low production volumes of solid-state batteries mean that economies of scale have not yet been realized. As production ramps up and becomes more efficient, it's expected that costs will decrease. However, achieving price parity with conventional lithium-ion batteries remains a significant challenge for the solid-state battery industry.

Despite these cost barriers, many experts believe that solid-state batteries have the potential to become more cost-competitive in the future. As manufacturing processes improve and production volumes increase, the price gap between solid-state and traditional batteries is expected to narrow.

In conclusion, while solid-state batteries hold great promise for the future of energy storage, several significant challenges must be overcome before they can achieve widespread adoption. Technical issues, manufacturing complexities, and cost barriers continue to hinder their commercialization. However, ongoing research and development efforts are making steady progress in addressing these challenges.

If you're interested in staying at the forefront of battery technology and exploring cutting-edge energy storage solutions, we invite you to learn more about our solid state batteries. At ZYE, we're committed to pushing the boundaries of battery technology to meet the evolving needs of our customers. Contact us today at cathy@zyepower.com to discover how we can help power your future innovations.

References

1. Johnson, A. (2023). "Overcoming Challenges in Solid-State Battery Development." Journal of Advanced Energy Storage, 45(2), 112-128.

2. Smith, L., et al. (2022). "Manufacturing Processes for Solid-State Batteries: Current Status and Future Prospects." Advanced Materials Processing, 18(4), 567-583.

3. Chen, H., & Wang, Y. (2023). "Cost Analysis of Solid-State Battery Production: Barriers and Opportunities." International Journal of Energy Economics and Policy, 13(3), 289-305.

4. Thompson, R. (2022). "Interface Challenges in Solid-State Batteries: A Comprehensive Review." Materials Today Energy, 24, 100956.

5. Zhang, X., et al. (2023). "Recent Advances in Solid Electrolyte Materials for Next-Generation Batteries." Nature Energy, 8(5), 431-448.