What are the challenges and limitations of using solid-state batteries in drones?

2025-07-21

Challenges and Limitations of Solid-State Batteries in Drones: Navigating the Roadblocks to Adoption

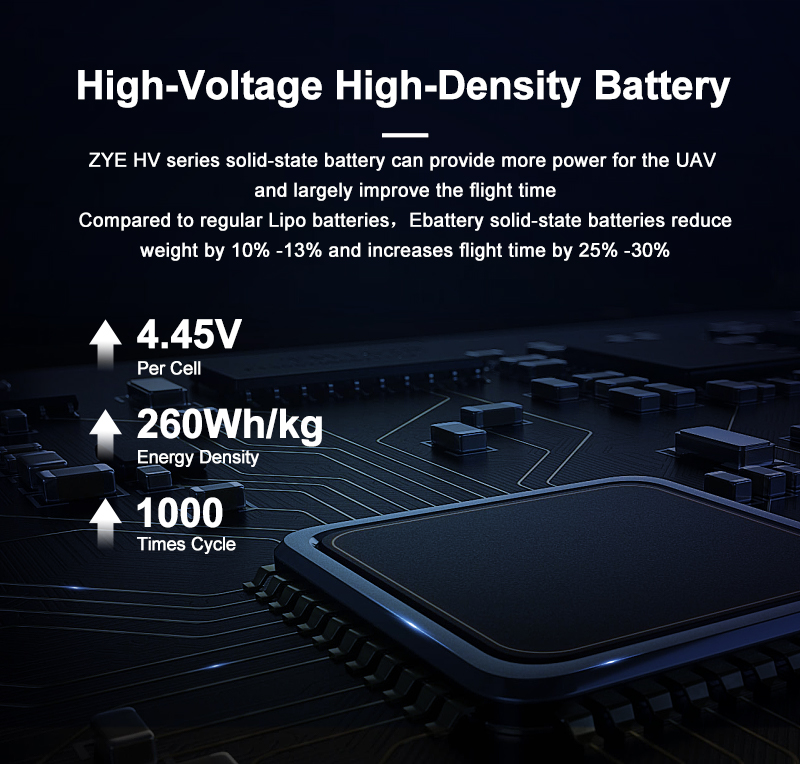

solid-state-battery have emerged as a promising alternative to lithium-ion (Li-ion) batteries for drones, offering advantages like higher energy density, improved safety, and better temperature tolerance. However, their path to widespread adoption in the drone industry is hindered by a set of technical, economic, and practical challenges. Let’s break down these limitations and why they matter for drone operators, manufacturers, and industries relying on unmanned aerial vehicles (UAVs).

1. High Production Costs and Limited Scalability

One of the most significant barriers to solid state battery adoption in drones is cost. Solid-state technology remains expensive to produce at scale, primarily due to:

Specialized Materials: Many solid state batteries use high-cost components, such as lithium metal anodes, ceramic electrolytes (e.g., garnet or sulfide-based), or ultra-pure raw materials. These materials are pricier than the graphite anodes and liquid electrolytes in Li-ion batteries.

Complex Manufacturing: Producing solid state batteries requires precision manufacturing processes, such as thin-film deposition for electrolytes or controlled environments to prevent contamination. These steps are more labor-intensive and require specialized equipment, driving up production costs.

2. Cycle Life and Degradation Concerns

Drones are workhorses—many operate daily, requiring frequent charging and discharging cycles. For solid state batteries, cycle life (the number of charge-discharge cycles before capacity drops below 80%) is a critical limitation.

This degradation stems from interfacial instability between the solid electrolyte and electrodes. Over time, chemical reactions at these interfaces form resistive layers, reducing conductivity and capacity. For example, lithium metal anodes (common in solid state batteries) can form dendrites—tiny, needle-like structures—that pierce the solid electrolyte, causing short circuits or capacity loss. While ceramic electrolytes are more resistant to dendrites than liquid ones, they aren’t impervious, especially under high discharge rates.

3. Mechanical Fragility and Vibration Sensitivity

Drones operate in dynamic, often harsh environments—they vibrate during flight, withstand impacts from wind gusts, or even crash. solid-state-batteries, particularly those using ceramic electrolytes, are mechanically brittle compared to the flexible, pouch-style Li-ion batteries common in drones.

4. Temperature and Discharge Rate Limitations

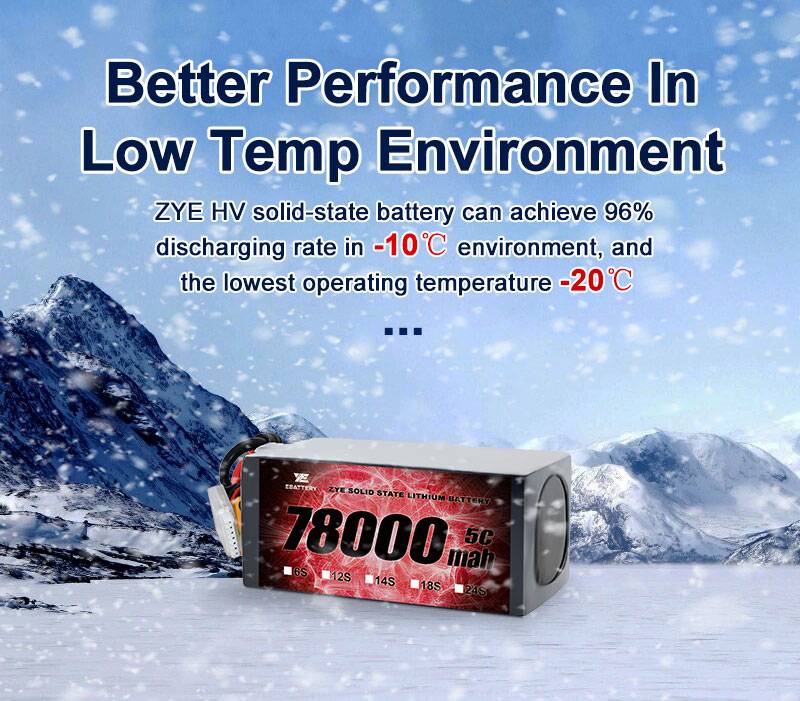

While solid state batteries perform better than Li-ion batteries in extreme temperatures, they aren’t universally robust. Many solid electrolytes have narrow optimal temperature ranges for conductivity.

5. Form Factor and Integration Challenges

Drones come in diverse shapes and sizes, from compact quadcopters to fixed-wing UAVs with slim fuselages. This variety demands batteries with flexible form factors—pouches, cylinders, or custom shapes. Solid state batteries, especially those with ceramic electrolytes, are often rigid and difficult to mold into non-standard sizes. Polymer electrolytes offer more flexibility but sacrifice conductivity, making them unsuitable for high-power drones .

6. Reliability is Mission-critical

A lab-tested solid state batteries might achieve 90 minutes of flight time in controlled conditions, but in real-world use—with wind resistance, payload shifts, or temperature swings—actual flight time could drop by 20–30%. This unpredictability makes industries like logistics or emergency services hesitant to adopt SSBs.

Conclusion: Progress, but Not Perfection

Solid-state batteries hold immense promise for drones, but their current limitations—cost, cycle life, fragility, and integration challenges—prevent them from displacing Li-ion batteries overnight. These hurdles are surmountable: advances in electrolyte chemistry (e.g., hybrid ceramic-polymer electrolytes), scalable manufacturing, and dendrite-resistant designs are already addressing key issues.

For now, solid-state-batteries are best suited for niche drone applications where their strengths (safety, high energy density) outweigh their costs—such as military UAVs or high-end industrial inspections. As technology matures, however, we can expect solid-state batteries to gradually (penetrate) the drone market, unlocking new possibilities for flight time and versatility. Until then, Li-ion remains the pragmatic choice for most drone operators.

For more information about high energy density solid state battery and our range of high-performance energy storage solutions, please don't hesitate to contact us at coco@zyepower.com. Our team of experts is ready to help you find the perfect battery solution for your needs.